In engineering, computational fluid mechanics optimizes design and efficiency. For aerospace, it boosts aircraft performance by enhancing airflow simulation. In automotive, it refines vehicle aerodynamics and accelerates design adjustments without physical prototypes. Energy industries benefit from enhanced efficiency in optimizing systems like wind turbines and offshore platforms. In biomedical fields, it's essential for analyzing blood flow and respiratory conditions. Environmental assessments rely on it for evaluating pollutant dispersion and water quality. Discover how computational fluid mechanics drives innovation and optimization across diverse industries.

Key Takeaways

- Optimizes aircraft and rocket design.

- Enhances vehicle aerodynamics.

- Improves energy sector efficiency.

- Analyzes biomedical fluid dynamics.

- Aids in environmental impact assessments.

Aerospace Industry Applications

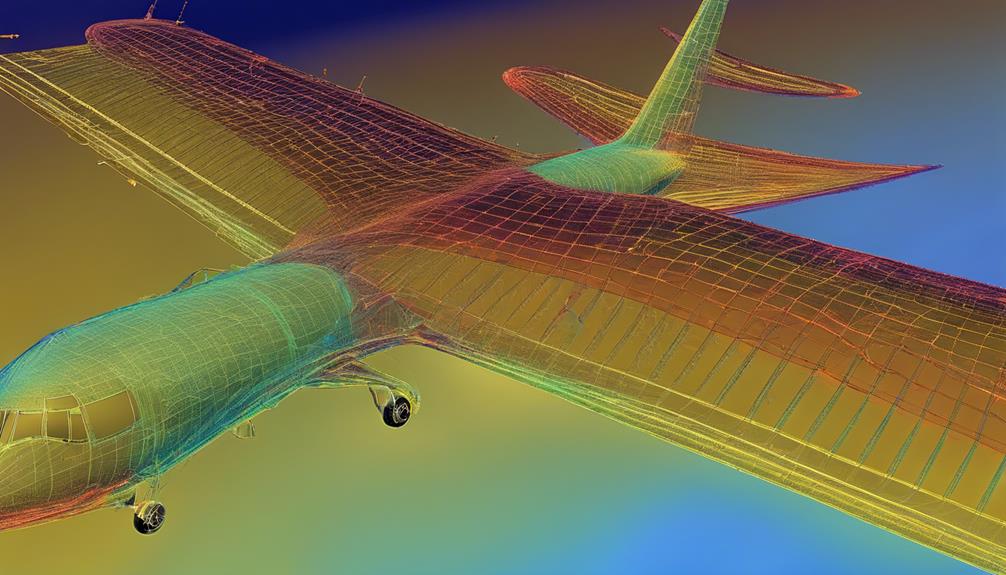

In the aerospace industry, computational fluid mechanics plays a pivotal role in optimizing aircraft design and performance. By simulating airflow over various components of an aircraft, engineers can analyze and enhance the aerodynamic efficiency, leading to improved aircraft performance. This technology allows for the evaluation of different wing shapes, engine placements, and overall configurations to maximize lift, reduce drag, and enhance fuel efficiency.

Moreover, computational fluid mechanics is vital in the design and analysis of rocket propulsion systems. By modeling the combustion process within rocket engines, engineers can fine-tune parameters such as fuel injection, combustion chamber geometry, and nozzle design to achieve peak thrust and efficiency.

This enables the development of powerful and reliable propulsion systems for space exploration and satellite deployment missions.

Automotive Design Optimization

Optimizing automotive design through computational fluid mechanics enhances vehicle performance and efficiency. By utilizing airflow simulation, engineers can analyze and improve the aerodynamic efficiency of vehicles. This process involves studying how air flows around the vehicle body, identifying areas of high drag, and making design modifications to reduce resistance and improve fuel economy.

Through computational fluid mechanics, automotive manufacturers can simulate various scenarios and test different design configurations without the need for physical prototypes. This not only accelerates the design process but also allows for more precise adjustments to optimize aerodynamics and overall vehicle performance.

Energy Sector Innovations

Enhancing energy sector efficiency through computational fluid mechanics involves revolutionizing traditional approaches to fluid dynamics analysis. By leveraging advanced simulations, engineers can optimize the design and operation of renewable energy systems such as wind turbines and solar panels.

Computational fluid mechanics plays a vital role in enhancing the performance of offshore platforms used for oil and gas extraction by analyzing fluid flow patterns and optimizing structural designs to withstand harsh marine environments.

Renewable energy technologies like tidal and wave energy converters benefit from computational fluid mechanics by enabling engineers to predict and optimize energy extraction efficiency. Offshore wind farms also rely on these computational tools to assess wind patterns and optimize turbine layouts for maximum energy production.

Additionally, computational fluid mechanics aids in the development of innovative energy storage solutions, such as pumped hydroelectric storage, by simulating fluid flow dynamics within storage reservoirs.

Innovations in the energy sector driven by computational fluid mechanics are essential for shifting towards a sustainable and efficient energy future.

Biomedical Fluid Dynamics

Analyzing blood flow patterns in the human cardiovascular system presents a vital application of computational fluid mechanics in the field of biomedical engineering. Cardiovascular simulations play an essential role in understanding the complexities of blood flow, pressure distributions, and potential issues such as plaque buildup or abnormal flow patterns. By utilizing computational models, researchers and engineers can simulate different scenarios to predict how changes in the cardiovascular system may impact overall health.

In addition to cardiovascular simulations, computational fluid mechanics is also employed in studying respiratory mechanics. This involves analyzing airflow dynamics in the respiratory system to enhance the understanding of conditions like asthma, chronic obstructive pulmonary disease (COPD), and the effectiveness of various treatments. By simulating airflow patterns and pressure changes within the lungs, researchers can gain valuable insights into how respiratory conditions develop and progress.

Environmental Impact Assessments

Exploring the application of computational fluid mechanics in environmental impact assessments involves examining the fluid dynamics of natural systems to understand the potential consequences of human activities on the environment. By utilizing advanced simulations and modeling techniques, engineers can evaluate the dispersion of air pollutants and forecast their impact on air quality. Additionally, water quality modeling enables the prediction of pollutant transport in aquatic systems, aiding in the identification of potential contamination sources and the development of mitigation strategies.

To provide a clearer picture, let's delve into a comparison between air pollution dispersion and water quality modeling:

| Air Pollution Dispersion | Water Quality Modeling | Benefits |

|---|---|---|

| Predicts movement of pollutants in the air | Models the transport of contaminants in water bodies | Helps in evaluating health risks |

| Assists in designing effective emission control strategies | Aids in identifying pollution sources and designing remediation plans | Supports sustainable environmental management |

| Enables compliance with regulatory standards | Facilitates the protection and restoration of aquatic ecosystems | Promotes environmental sustainability |

Conclusion

Overall, computational fluid mechanics plays a vital role in various engineering applications, including aerospace, automotive, energy, biomedical, and environmental industries.

By utilizing advanced simulation techniques, engineers are able to optimize designs, improve efficiency, and reduce environmental impacts.

The versatility and effectiveness of computational fluid mechanics make it an essential tool for solving complex fluid dynamics problems in a wide range of engineering disciplines.